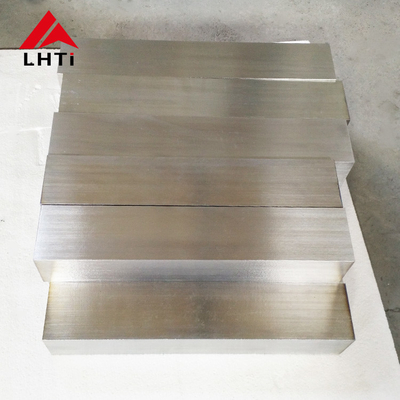

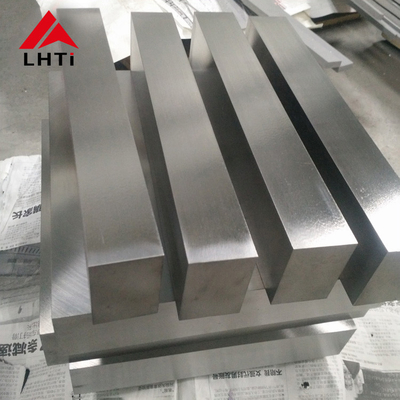

GR5 Titanium alloy block titanium alloy cube

Die forging process: forging blank blanking; Forging billet heating; Roll forging blank; Die forging; Trimming; Punching; Correction; Intermediate inspection to inspect forgings for dimensions and surface defects; Heat treatment of forgings to eliminate forging stress and improve metal cutting performance; Cleaning, mainly to remove the surface oxide scale; Correction; In general, forgings should be inspected for appearance and hardness, while important forgings should be inspected for chemical composition analysis, mechanical properties, residual stress and nondestructive testing.

| Chemical requirements | |||||||||||

| N | C | H | Fe | O | Al | V | Pd | Mo | Ni | Ti | |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5~6.75 | 3.5~4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12~0.25 | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2~0.4 | 0.6~0.9 | bal |

| Tensile requirements | |||||

| Grade | Tensile srength(min) | Yeild strength(mm) | Elongation(%) | ||

| KSI | MPa | Ksi | MPa | ||

| 1 | 35 | 240 | 20 | 138 | 24 |

| 2 | 50 | 345 | 40 | 275 | 20 |

| 5 | 130 | 895 | 120 | 828 | 10 |

| 7 | 50 | 345 | 40 | 275 | 20 |

| 12 | 70 | 438 | 50 | 345 | 18 |

![]()