Product Detection of Pickled Titanium Plate

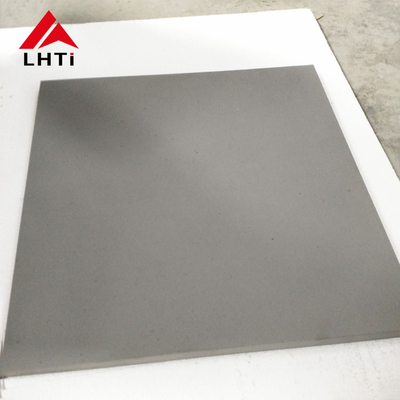

Visual inspection to check the surface quality, ensuring it without any flaw, black dot, and any other defects.

Ultrasonic Flaw Detection to make sure there are no inside defects.

Chemical Composition Detection to make sure all chemical component can satisfy customers demands

Mechanical Features testing to make sure products have satisfying mechanical features before delivery.

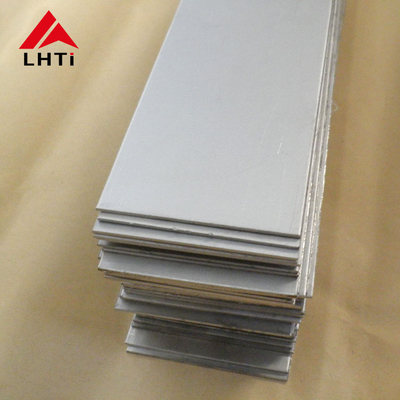

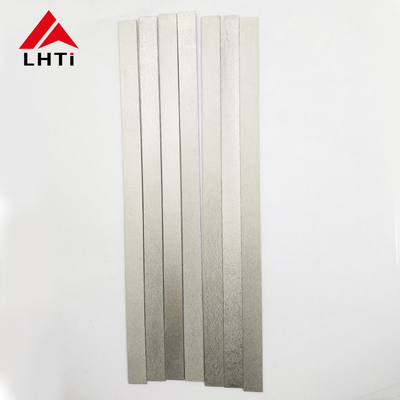

We supply titanium sheet in a range of surface finishes which is produced typically by pickling and sandblasting as per customer's requirements to ensure the required quality finish. Right rolling technology and annealing technology can also contribute a lot to provide the perfect titanium sheet.

| Standard | ASTM B265, AMS 4911, AMS 4916, ASTM F67, ASTM F136 |

|---|---|

| Grade | Gr1, Gr2, Gr3, Gr4, Gr5, Gr7, Gr9,, Gr23, etc. |

| Thickness | 0.5mm - 30mm |

| Width | 10mm - 2500mm |

| Technology | Hot-rolled, cold-rolled, hot forging, machining |

| Condition | Cold rolled(Y), hot rolled(R), annealed (M), quenching(C) |

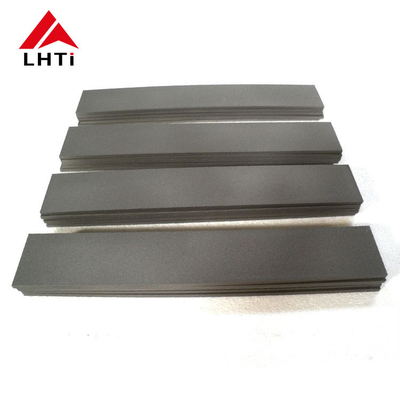

| Surface | Pickling surface, polished surface, black surface |