Titanium Foil roll Detection

We perform a visual inspection to check the surface quality and ensure no flaw, blackspots, and any other defects.

We also do chemical composition detection, making sure all chemical components meet demands.

Mechanical features testing, making sure all titanium foils have satisfying mechanical features before delivery.

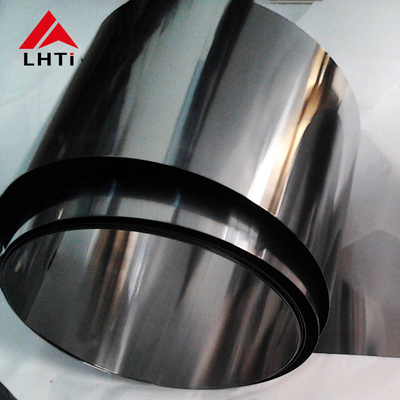

Quality Assurance of Titanium Foil roll

we perform these tasks to ensure quality according to globally recognized standards, such as ASTM, AMS, ASME, JIS, MIL.

Chemical Composition, Mechanical properties, making sure no defects inside the products.

ISO Quality Management System.