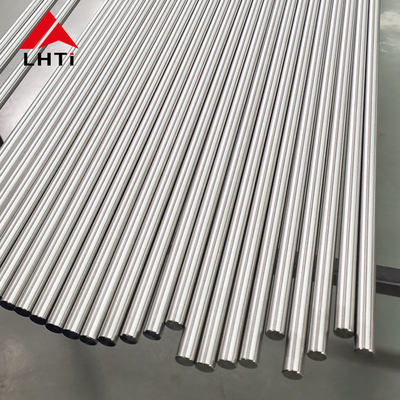

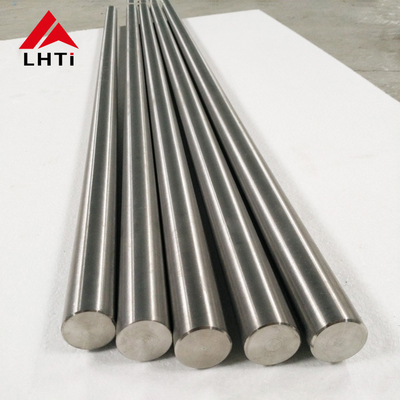

Titanium alloy bar are used in many challenging applications in the aerospace, medical, industrial, and oil and gas industries, and due to its unique combination of high strength, light weight, corrosion resistance, biocompatibility and higher temperature performance Selected.

Die forging process: forging blank blanking; Forging billet heating; Roll forging blank; Die forging; Trimming; Punching; Correction; Intermediate inspection to inspect forgings for dimensions and surface defects; Heat treatment of forgings to eliminate forging stress and improve metal cutting performance; Cleaning, mainly to remove the surface oxide scale; Correction; In general, forgings should be inspected for appearance and hardness, while important forgings should be inspected for chemical composition analysis, mechanical properties, residual stress and nondestructive testing.