Application:Industry, heat exchanger

Grade:Gr2

Standard:ASTM B338

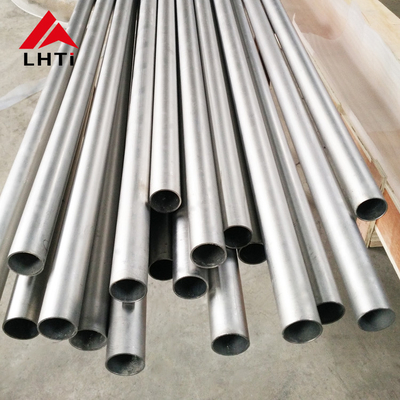

Diameter:2.5~150mm

Length:500-15000mm

Density:4.51g/cm3

Technique:Cold Reduction

Shape:Round

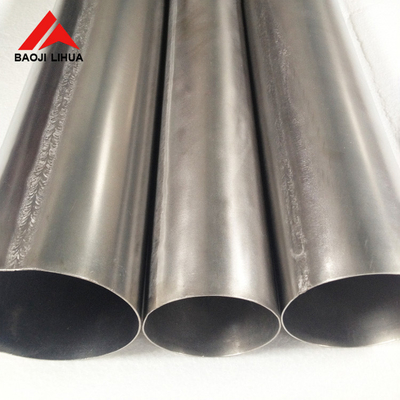

Surface:polished

Color:sliver

The ASTM B338 GR2 Welded Titanium Alloy Tube is equipped with good corrosion resistance, and there is a uniform and dense oxide film immediately formed on the titanium surface in the atmosphere. On the other hand, it has the ability to resist the erosion of various media. There are various kinds of shape options, thus to provide more choices to meet need.

Product Description

The ASTM B338 GR2 Welded Titanium Alloy Tube is a tube made of titanium alloy, which has the advantage of high mechanical properties, excellent stamping properties, and the cutting performance is good. In addition, the ASTM B338 GR2 Welded Titanium Alloy Tube has high corrosion resistance to chloride, sulfide and ammonia. The corrosion resistance of titanium in seawater is higher than that of aluminum alloys, stainless steels, and nickel-based alloys. Due to the excellent medium temperature strength, the temperature several hundred degrees is higher than aluminum alloy, which can still maintain the required strength at medium temperature.